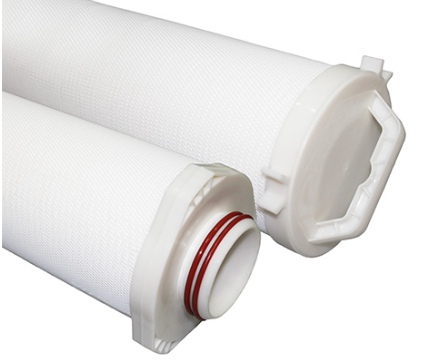

High Flow Platted Cartridges

High Flow Cartridge Filter

High Flow Cartridge Filter is a large-diameter, pleated filter cartridge specially designed to handle high flow rates and long service life with fewer cartridges compared to conventional filters. These are widely used in industrial water treatment, power plants, petrochemicals, food & beverage, and pharmaceuticals.

Key Features of High Flow Cartridge Filters:

High Flow Capacity: Each cartridge can handle 20–70 m³/hr depending on design and fluid type.

Large Diameter: Typically 6"–6.75" (152–165 mm) diameter, with lengths of 20", 40", or 60".

Pleated Construction: Provides high filtration area, reduces pressure drop, and extends service life.